Long term professional working relationship

Siemens Gamesa have worked with Mascot globally for many years. The quality, comfort and reliability of their garments consistently scores high with wearers, from technicians to factory staff working both on and offshore.

So in 2016, when it came to opening our blade factory in Hull, they were the clear choice. Kitting out over 900 new employees with over 20,000 items was no easy task but Mascot rose to the occasion and made the process as smooth as possible. From supplying sizing kits, delivering at short notice and ensuring production runs on certain lines met our needs, nothing was too much trouble. They also worked tirelessly with our other key suppliers such as our integrator who manages the orders through to the laundry company would be handling all these garments. When we initially did look who else was in the market many other manufacturers over promised and when it came to it couldn’t provide anywhere near the service levels required.

Working Together

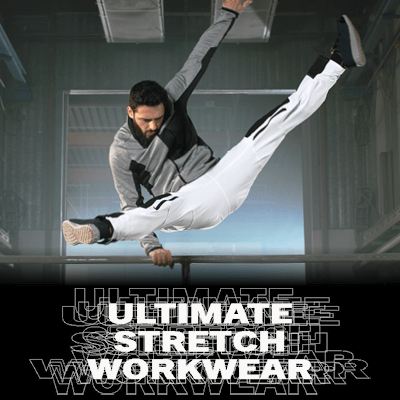

Since then, we have worked closely together to ensure we continuously have the right products for the right environments. The launch of the 17179 4-way stretch trouser was a particular highlight with wearers. It massively increased the level of comfort whilst also being lighter weight and therefore much cooler. This is increasingly important when working in challenging locations such as inside wind turbine blades. And importantly it was still cost effective.

Sustainability

A key focus topic for SGRE is sustainability and it’s reassuring this is also the case for Mascot. Their new tops in the CROSSOVER range made of recycled polyester and organic cotton have recently been launched across our business in the UK with good feedback. Our employees are actively seeking out these sustainable products manufactured with recycled and organic materials so it’s important for us as a business to provide them. Getting them from a brand they trust makes the transition much easier.

As a procurement professional I’ve found them excellent to deal with. We look forward to working with Mascot for many more years and see what exciting innovations they come up with!

Matt Scaum

Senior Buyer

Siemens-Gamesa